2023 Global Market Outlook: Polypropylene

Introduction

Polypropylene (PP) prices and margins declined globally in 2022 and are anticipated to see further weakness in 2023. Recently, China has reduced its net import needs for polypropylene (PP), while North America is expected to follow a similar trend in the coming years. New capacity is coming online even as the overall demand outlook has weakened in line with reduced expectations surrounding global economic growth.

Analyst overview

PP production and operating rates are forecast to recover in 2023 as global economies are expected to improve throughout the year. Another 45,000 tonnes of capacity will be added to the industry after Invista finishes expansion work at their Longview, TX, unit in 2023, following 975,000 tonnes of new capacity added in late 2022 from ExxonMobil and Heartland Polymers. Formosa’s new PP unit in Point Comfort, TX, has been pushed from 2023 to the end of 2024. Given the expected long market conditions, PP imports will need to decline while exports should increase.

After falling 18 cents per pound in the second half of 2022, PP margins are forecast to decline slightly in 2023 as low operating rates and increased supply provide pricing pressure to a long market. Propylene feedstock prices will be volatile in 2023 due to new derivative demand tightening the market in the first half of the year followed by propylene supply relief with the startup of Enterprise’s second PDH unit by the second half of the year. This propylene volatility will cause PP price volatility in 2023 as well.

Author:

Kimberly Haberkost joined Chemical Data as Director of Olefins in January of 2019. She has over 20 years of chemical industry experience. Most of her career has been focused on the commercial side of the business with experience in both sales and purchasing for multiple corporations. Kim heads the ethylene, propylene, and PP products for CDI’s portfolio. For Chemical Data’s MFA report, she writes the Petrochemical Feedstock section.

In her industry career, Kim has over 8 years of experience selling polypropylene and polyethylene. She also has 12 years of experience in olefins including pipeline scheduling, market analysis, and propylene/ethylene purchasing. She has worked for CPChem, FHR, and Braskem before joining CDI. Kim graduated with honors from Virginia Tech in 2002 with a Bachelor of Science degree in Chemical Engineering and a minor in mathematics.

US PP demand outlook weak as new capacity starts up

The US polypropylene industry is heading into 2023 facing a weak demand outlook amid a recessionary environment even as new capacity came online late in 2022.

Weak demand through the second half of 2022 has resulted in average industry operating rates remaining below 80% from August through December, according to data from the American Chemistry Council (ACC) and Vault Consulting, with operating rates dropping below 70% in October.

Consumer spending slowed through the second half of the year as fears of recession and high inflation rates cut into demand. US manufacturing activity contracted for the first time in 30 months in November while a panel of business economists put the risk of a US recession in 2023 as greater than 50%.

These factors are expected to keep PP demand weak into 2023, with industry participants commenting that inventory levels are high across the chain, suggesting that the industry would need some time to digest these inventory levels even if demand were to return to more normal levels, which is not expected until at least the second half of 2023.

New capacity

ExxonMobil announced the successful start-up of a new 450,000 tonnes/year PP plant in Baton Rouge, Louisiana, in November while Heartland Polymers is in the commissioning phase of its propane dehydrogenation (PDH) unit at its Alberta, Canada facility.

While Heartland Polymers has been running its 525,000 tonnes/year PP plant for some time now, the plant has been at low operating rates while waiting for the PDH unit to start up. Therefore, the start-up of the PDH plant will enable the company to start running at full capacity.

Overall, the PP industry is adding just under 1 million tonnes/year of new capacity during a period of falling demand and the additional capacity is likely to maintain pressure on prices and margins through at least the first half of 2023.

Imports and exports

Over the first 10 months of 2022, imports of PP into the US declined by 25.9% while exports fell by 1.4%, according to data from the ICIS Supply and Demand Database.

Imports had increased considerably in 2021 as demand was strong and the industry experienced a large number of unexpected outages due to the impact of the February 2021 Texas freeze.

Weaker demand as well as the lack of any major production disruptions over the past year have helped pull down import numbers while the industry will be seeking to raise export numbers in the new year to help pare down inventories.

With capacity expanding in North America at a faster rate than demand growth, ICIS is projecting that North America will switch from being a net importer to a net exporter of PP over the next few years.

With northeast Asia also having recently flipped from a net import to a net export position, global trade flows will need to rebalance over the next few years.

PP sellers became more active in the export markets towards the end of the year in an effort to reduce excess inventory levels after export volumes had remained thin for most of 2020 and 2021 as the domestic market offered better netbacks relative to overseas sales.

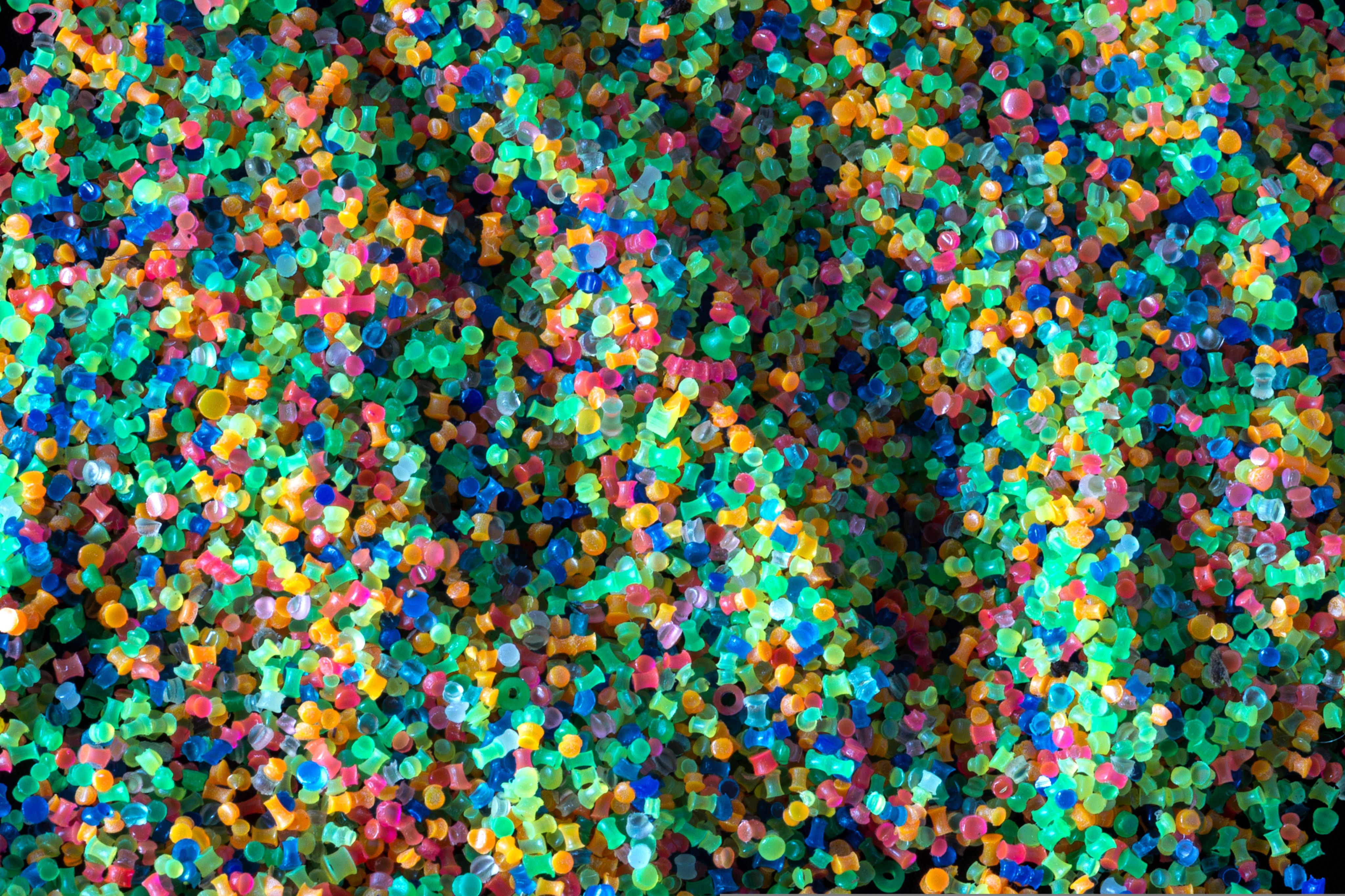

PP is used for packaging, ropes, carpets, plastic parts, loudspeakers and automotive parts.

Major US PP producers include Braskem, ExxonMobil, Formosa, INEOS, LyondellBasell, Pinnacle Polymers, Phillips 66 and Total Petrochemicals.

Author:

Zachary Moore joined ICIS in 2016 and currently works as senior editor manager for the Americas region. He covers North American markets for major commodity polymers such as polyethylene, polypropylene and polystyrene along with the polyurethanes chain in addition to assisting in coverage of olefins and aromatics.

Prior to joining ICIS, Zachary covered commodity polymer markets in Asia and Turkey for ChemOrbis as Assistant Manager of Market Intelligence. While working with ChemOrbis, Zachary helped establish their office in Kuala Lumpur, Malaysia and establish standards and methodologies for their stand alone Southeast Asia polymer reports. Zachary was also responsible for overseeing the editorial quality of coverage of the China polymer markets while assisting in coverage of Turkish polymer markets.

He has more than 16 years’ experience in the petrochemical and plastic markets as a markets reporter, researcher and analyst.

Zachary holds a BBA in economics from Georgia State University and an MA from the University of North Carolina-Greensboro.

Europe PE, PP players hope for uneventful year

A year of straightforward mundanity would be very welcome for most polymer players in 2023.

Brexit, the coronavirus, logistics chaos, war and rising inflation. These past few years have been an unpredictable mix of events and trends, each fundamentally affecting domestic and international trade.

2022 saw European prices dislocate from other regions following a spike in gas prices in the wake of Russia’s invasion of Ukraine.

The effects of the coronavirus pandemic echoed through global logistics chains, giving European producers an advantage over imports for domestic business.

Unpredictable and expensive shipping rates meant that European sellers could claim a premium and maintain good order levels, as they could ensure that delivery times could be met. This was especially attractive in times of volatility.

Imports were often available at significantly lower prices than European product as exporters struggled to fill the hole in their orders left by China - which was under a lengthy lockdown.

2023 – a regression to mean

2023 will stand alone compared with previous years due to a number of reasons - but mainly because it is expected to see a return to normality.

One important distinction between this year and next will be the steady return of shipping costs to lower levels and more reliable delivery periods.

It will, however, mean increased competition for European producers from imports.

Higher energy prices in Europe, leading to inflated polymer prices, may also prove attractive for many exporters.

Much hinges on the fate of China following the government’s decision to ease its zero-COVID policy.

The effect of two-years of continuous lockdowns on Chinese demand has contributed to a major fall in polymer volumes in 2022. If Chinese demand returns, then the market's dynamics in 2023 are likely to be very different than in 2022.

There is also a question mark about when demand will return to China, and the answer is not so simple. Many analysts predict a wave of the omicron variant because the country has a low vaccination rate.

Supply

One fact masked by lockdowns is that China has steadily increased its self-reliance on polymer production, especially PP, and even more plants are due to come online this year.

"In terms of supply, [European] producers’ margins will continue under pressure because of high energy prices, along with massive new capacities coming onstream, especially in Asia, amid improved logistics," ICIS PP analyst Emialiano Basualto pointed out.

"For these reasons, European producers may lose competitiveness in the global PP market, facing a very aggressive spot market in 2023, especially if the Chinese market remains shaky," he added.

US output is also expanding and at the end of 2022, US sellers began to make increasingly aggressive polyethylene (PE) offers into Europe.

“Global PE capacity is forecast to grow by almost 6% year on year in 2023,” ICIS PE analyst Lorenzo Meazza said.

Serious congestion at Houston port and a healthy local market have kept US product at arm’s length for most of the year. However, a slump in US demand has coincided with an uneventful storm season this winter, meaning that a large push of US volume could be due to arrive soon.

In a rare development, a new US plant is due to open on the East Coast which will mean shorter transit times to Europe. It will also avoid any congestion problem at Houston. Most US polymer production takes place around the Gulf of Mexico.

Demand

As supply streams normalise, it is difficult to assess how demand will develop in 2023.

Demand is estimated to be 10-30% below expected from many sectors, in particular those that use commodity grades.

There is little reason to believe that buying activity will pick up much in Q1. A mild winter so far, has eased the demand for gas which in turn has reduced upward price pressure on polymers.

As the weather gets colder, however, rising energy prices will continue to limit consumer purchases as many will focus on covering their rising bills.

The spring may see a recovery as the weather warms and Chinese demand picks up after the Lunar New Year.

Year-on-year growth of around 2% is expected for Europe (excluding Turkey) in 2023," said ICIS polymer analyst Emialiano Basualto.

Price trends

A normalisation of the market could see a return to a more traditional price trend. In 2022, the gap between spot and contract widened by a large amount.

European producers were able to leverage their reliable delivery times to maintain higher prices, while desperate exporters made repeated attempts to discount to achieve sales on the spot market.

The gap between the two should narrow as the arrival of imports becomes more predictable.

A similar trend can be expected in the monomer and polymer spread which has more than doubled in the last few years but is now trending downwards.

For the time being, however, there may be a limit because polymer producers claim to be unable to reduce prices any further for fear of totally losing their margins.

Conclusion

A weak end to 2022 will likely continue into 2023, and as next year's global growth expectations are revised, 2023 could prove very challenging.

“PE demand projections for Europe have been recently revised downwards on the back of weakening economic conditions in key economies and in the region in general. Most recent data show around 1% year-on-year growth in PE demand in 2023, a significant slowdown after the 2% expected for 2022” ICIS PE analyst Lorenzo Meazza said.

Many players will focus solely on conserving what they have and new investments and ventures could be stifled by a safety-first attitude.

The hope is for a return to normal and a reduction in volatility - although we may still see more unpredictability for at least part of the year.

Author:

Ben Lake is the African and European polymers editor. He has been with ICIS for 6 years and has spent the majority of that time covering the polymers market.

9th ICIS World Polyolefins Conference

Engage with ICIS experts and industry leaders from the polyethylene (PE) and polypropylene (PP) value chains to discuss the most pressing global and regional market challenges.

The 9th World Polyolefins Conference will be taking place on 29-30 March 2023 at the Ritz-Carlton hotel in Vienna.

Evaluate key trends at the forefront of the industry to unearth your winning strategy to adapt and overcome future market challenges.

China’s PP capacity to expand amid global recession, policies bring uncertainties

China’s domestic polypropylene (PP) capacity will expand further in 2023 amid the bearish global economy. Although the gradual lifting of its zero-COVID policy may support the market, there are still uncertainties brought by policies and economic outlook.

The year 2022 was a challenging year for China’s PP market.

Costs surged following Russia's invasion of Ukraine, while the Chinese government’s strict zero-COVID policy had an adverse impact on the operation of derivative producers and PP demand.

China’s November official purchasing managers index (PMI) for the manufacturing sector dropped by 1.2 percentage points month on month to 48.0%, indicating an extended weakness in factory activities, data from the National Bureau of Statistics (NBS) showed.

Meanwhile, many PP producers were under margin pressure or even faced losses, which saw frequent output cuts or plant shutdowns.

On the supply side, China’s PP capacity increased by 2.8m tonnes/year so far in 2022. Oversupply dragged down PP prices compared with 2021.

In the overseas market, demand was capped by high inflation. Prices started to fall from the second quarter, narrowing the gap with prices in China. Therefore, the PP export market was not as strong as some Chinese market players expected in the beginning of 2022.

China’s PP exports hit the highest level of 2022 in April and then decreased. A total of 1.157m tonnes were exported in January-October 2022, up by only about 0.8% year on year.

With the increasing self-sufficiency rate, China’s PP imports decreased by 7.6% year on year in January-October 2022 to 3.667m tonnes.

More overseas sellers switched their attention to China in the second half of 2022 because overseas prices were falling and demand was weak.

The import arbitrage window opened and China’s PP imports grew significantly in September and October. The availability of competitively-priced import cargoes exerted stronger pressure on the supply side.

Looking into 2023, China’s PP capacity will continue to grow. A total of 5.55m tonnes/year of new capacity are expected to come on stream in December 2022 and in 2023, while the start-up of some units may be delayed to 2023.

The macroeconomy will bring some uncertainties to the PP market.

China’s GDP growth is projected at 4.4% for 2023, up from the projected 3.2% for 2022, according to the International Monetary Fund (IMF) – a bullish sign for China’s PP market.

On 23 November 2022, the People's Bank of China (PBOC) and the China Banking and Insurance Regulatory Commission (CBIRC) issued a 16-step guideline to support the development of the real estate industry.

The real estate market is not only a key derivative of the PP market itself, but also affects the household appliance market, another important downstream sector of PP. The issuance of the guideline may promote the consumption of PP pipe, yarn and copolymer.

However, some have showed concerns about the support from the real estate industry to China’s economy.

According to Jincy Varghese, ICIS demand analyst, “The Chinese construction sector continues to be on shaky ground, owing to its over-leveraged developers. Multiple developers have started defaulting on timely debt repayments.”

John Richardson, ICIS Senior Consultant, Asia, even said that China’s real-estate sector can hardly be turned around.

China’s zero-COVID policies and containment measures are also key factors impacting PP demand. Recently, China's zero-COVID stance has been relaxed, providing some support for economic recovery in 2023.

If the containment measures ease, the end-user demand for PP may gradually recover in the second half of 2023 and therefore render support to the market, according to Joey Zhou, ICIS Senior Analyst. However, this may be partially countered by increasing PP supply and the global recession.

Moreover, should producers continue to face margin pressure in 2023, some may continue to shut down units or cut run rates to reduce losses. This, combined with increasing supply from new plant start-ups, may have a short-term impact on China’s PP market.

In view of further increases in supply and uncertainties in domestic demand, the overseas market becomes a key outlet for China’s PP.

However, global GDP growth is projected to slow from an estimated 3.2% in 2022 to 2.7% in 2023, according to IMF, which casts uncertainty on the global economic outlook.

“The global economy is facing its biggest test since the World War II,” Kristalina Georgieva, Managing Director of IMF, said.

The bearish global economic outlook and a lack of cost advantage over cargoes from the Middle East, the US and Russia, may continue to curb China’s PP exports in 2023.

The drastic surge in PP exports seen in 2021, up by 227% from 2020, is unlikely to repeat.

Meanwhile, PP imports may fall further as domestic capacity keeps increasing.

However, the import arbitrage window may open temporarily if domestic demand rebounds after the gradual lifting of the zero-COVID policy, amid a subdued overseas market.

Moreover, some specialty PP materials still need to be imported due to technical barriers at domestic units.

Therefore, apart from increasing domestic supply, China’s PP market may also face the challenges of an open import arbitrage window from time to time.

Author:

Zhibo Xiao is an industry analyst for China’s polypropylene market at ICIS. He has more than 7 years of experience in the chemical industry. He holds a Master’s Degree with Distinction from the UK and has experience in the oil and gas initial processing plant in Petrochina.

Asia PP's potential oversupply may outweigh China's demand recovery

Possible oversupply in Asia's polypropylene (PP) market may outweigh the impact of demand recovery in China in 2023.

After a slow 2022, China's easing of COVID-19 restrictions gave the PP market in Asia a glimmer of hope for demand recovery going forward.

However, the actual impact may take more time than expected to be realised.

"The number of infections in China since they opened up has been very high," a supplier of dutiable PP cargoes in southeast Asia said.

"This is affecting end-product consumption. With Lunar New Year taking place much earlier than usual this year, demand there may not pick up until after February at least," the supplier added

In southeast Asia, converters remained alarmed by a lack of finished goods orders and do not expect the situation to improve until late Q1 2023.

Some converters have scaled down their production activities further in Q4 2022 as they struggled to move their end-products.

"Even our low-value products are not moving as fast as they used to," an Indonesian converter said. "This is a clear sign that the economy is struggling and people are not spending their money."

A separate Indonesian converter echoed the same sentiment, adding that possible demand pick-up may only surface from February onwards ahead of the Eid ul-Fitr season in late April.

Even so, buying sentiment remained affected by potential supply lengthening.

A major southeast Asian producer is expected to restart their complex sometime in Q1 2023, while a new producer is starting to ramp up commercial operations.

On top of that, a slew of new capacities either has come or will be coming on stream in China.

According to Joey Zhou, Senior Analyst at ICIS, "Although some PP projects will be delayed further to 2024, impacted by the pandemic and poor margins, there will be a strong rise in new capacity in Asia in 2023. A total of some 5.6m tonnes of effective new capacity are expected in China in 2023. Other new projects in Asia will come from India, Vietnam and Malaysia. We expect China PP average utilisation rates to decrease to about 77% in 2023, down from 84% in 2022."

"Let's not forget that most producers were running at reduced run rates and some of them were shut down in Q4 2022," a southeast Asian PP supplier said. "So, supply may be ample going forward and some buyers are mindful of that."

Most buyers in China and southeast Asia have been maintaining lean inventory as they observe how the supply-demand situation develops.

"Some buyers think that they can get cargoes easily from either domestic suppliers or from the import market, so they don't want to stock up at the moment," a southeast Asian trader said.

On top of that, inflation and economic uncertainties continued to be key concerns, especially in Vietnam.

Some converters have been facing pressure from higher interest rate and difficulty in securing new credit lines from banks.

With cash flow tightening, the cost of inventory is increasing, so converters are unlikely to carry excess feedstock inventories unless end-product demand starts to pick up.

"We may see some demand pick-ups here and there as usual, but nothing spectacular for maybe first half of the year," a southeast Asian trader said. "After that, hopefully the economic conditions improve and spending goes up, then maybe we will have a better second half of the year."

Author:

Jackie Wong is a Senior Editor at ICIS, covering the polypropylene market in Asia Pacific. Prior to this, he has covered the oleochemical value chain, including products such as fatty acids, fatty alcohols, glycerine and soap noodles.

As chemical markets shift quickly, there is a need to act decisively, strive for better, and make changes that drive a difference in the long-term. ICIS is committed to partnering with the industry to optimise the world’s resources, connecting the value chain and achieving efficient and sustainable growth for the chemical industry.

Access to expert insights on the latest industry developments and tracking market changes are vital in making sustainable business decisions.